Conduction Cooling in Power Supplies

As the rated output power of a power supply increases, the means of delivering power efficiently becomes more difficult due to the conversion losses in the form of heat. These losses become more apparent when the power rating of the supply increases. Traditional medium or high-rated power supplies use free-air convection or require forced air cooling to dissipate heat effectively, both of which have their own benefits and drawbacks. Convection cooling relies on natural-moving free air, but often results in the supply being derated in power since it is not an efficient way to dissipate heat. Fans are more effective in removing heat from hard-working components but introduce their own parasitic characteristics such as reducing reliability and introducing audible noise. Systems engineers and power supply specifiers are requesting more and more fanless power supplies. Conduction-cooled power supplies offer an alternative that incorporates the benefits of both cooling methods.

How Do They Work?

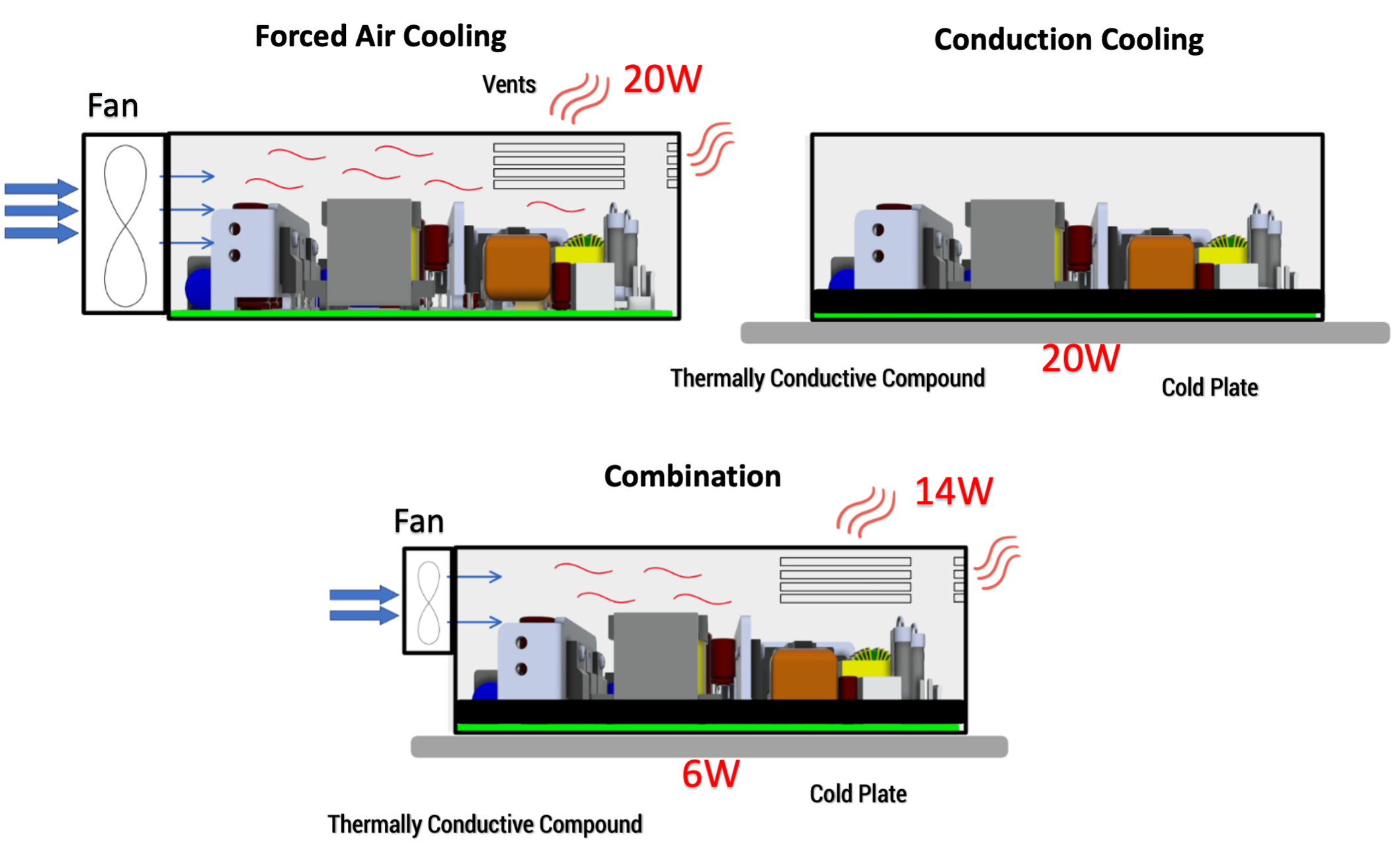

The general, overall design of conduction-cooled power supplies is not exceedingly different from traditional convection or forced air variants. In fact, some products offer multiple variants that can be used with forced air, conduction, or a combination of the two. Heat generation culprits such as rectifiers and MOSFETs/transistors are placed on or strategically as close to the surface of the PCB as possible to maximise the conduction of heat between the surface of the device and the mounting plate. These components are also partially encapsulated or potted with a thermally conductive compound on the surface of the PCB to assist in the transfer of heat to the outside plate. The supply requires a ‘cold plate’, or temperature-controlled mounting surface with certain thermal characteristics in order to dissipate heat efficiently. Specifications for mounting are given in the power supply datasheet.

Figure 1: Graphic showing effective cooling methods in a U-bracket/enclosed power supply.

Why Consider Conduction-Cooled?

Fan cooling in power electronics has always been a double-edged sword, producing a trade-off between reliability and effective heat dissipation. Fans can collect dust from the outside environment and blow it into the supply, over time causing insufficient air to move throughout the enclosure which can lead to overheating. Conduction-cooled power supplies offer the design reliability of free air convection, and do not require the use of forced air to achieve their full potential. They produce equivalent, if not better efficiency levels than their forced air counterpart. With no moving parts, conduction cooling can be a much more reliable way of getting the most out of your power supply. They also can be used in applications where natural convection or forced air is not an option. Allowing for more flexibility when designing them into a system. Conduction-cooled supplies are also perfect for audible noise-sensitive applications, where the constant whir of a fan is not desired.

Figure 2: PAA product images

PAA Conduction-Cooled Series

TT Electronics’ PAA conduction-cooled series offers 130-500 Watts in a power-dense package. With high efficiency, increased MTBF, and lower maintenance costs, this series proves to be a superior alternative to traditional forced air or convection-cooled options. Depending on the nature of the application, this series can be used solely with a ‘cold plate’, or a combination of forced air and conduction cooling, as well as with just a traditional fan. This gives more flexibility for the user by allowing a wider range of possibilities when designing their system. Some applications include audio equipment, traffic control monitoring equipment, and outdoor locker products.

Partner With An Expert

The first step to optimising power conversion in your next design is to partner with a power supply expert. The engineering team at TT Electronics can work with you, as an extension of your own engineering team, to identify and deploy the ideal power supply solution. Talk to our team today about a free load characterisation study – a great way to ensure the system drives the power supply requirements, and not the other way around.