One way your business can improve their profits and reduce production times is by adopting a lean manufacturing or lean production approach. It is a way to eliminate waste and improve efficiency in a manufacturing environment. Lean manufacturing principles need to lead the conversation for the whole enterprise to achieve lean.

As a global manufacturing solutions provider, we are dedicated to state of the art manufacturing systems. Our dedication brings you the most successful systematic approaches of identifying and eliminating waste through the LEAN concepts and tools. In this article, we cover increasing quality with no loss to productivity, ensuring safety and reducing cost through the principles of lean manufacturing.

Chapters

Chapter 1

Lean Manufacturing Background and History to Today

Early developments in lean manufacturing were centered around automation, standardisation of work and developments in manufacturing theory. The first person to integrate an entire production process (assembly line) was Henry Ford.

Having the knowledge of Ford's system, engineers at Toyota, began the process of trying to perfect "flow production". They wanted to eliminate waste and inefficiency in its manufacturing operations. It later became known as TPS (Toyota Production System). A system that focused the flow of the product through the total process.

Taiichi Ohno, Industrial Engineer and Businessman, "Father of the Toyota Production System" once said,

"All we are doing is looking at the timeline from the moment the customer gives us an order to the point when we collect the cash, and we are reducing the time line by reducing the non-value adding wastes."

A Lean Manufacturing timeline from the Eagle Group displays the major innovations of American and Japanese manufacturers–namely Ford, GM and Toyota–in their quest for efficiency, quality and consistency.

Looking forward...

Based on a 5-year study on the future of the automobile, the book, "The Machine That Changed the World" (1990) by James P. Womack, Daniel Roos, and Daniel T. Jones was written to explain the story of mass production versus lean manufacturing and why lean wins.

In a follow-up volume, "Lean Thinking" (1996), Womack and Jones continued to champion the benefits of lean manufacturing and lean transformation. The main lean manufacturing principles outlined to surface were:

Specify the value desired by the customer (customer's needs)

Identify the value stream for each product providing that value and challenge all of the wasted steps (where are the inefficiencies)

Make the product flow continuously through the remaining value-added steps (product flows smoothly toward the customer, test the process)

Introduce pull between all steps where continuous flow is possible

Manage toward perfection so that the number of steps and the amount of time and information needed to serve the customer continually falls (continue to strive for ways to reduce waste)

source: lean.org

Lean principles teach businesses to become flexible. It offers opportunities for organisations to continue to grow and improve.

Chapter 2

Lean Manufacturing Principles with [Kaizen]

Based on the Lean Enterprise Institute (LEI), the five-step thought process for implementation of lean techniques are value, value stream, flow, pull, and perfection.

Accomplishing all the steps that lead to perfection is no small task. There is a need for continuous improvement (kaizen) "change for the better" at all times.

Kaizen is the Japanese word for "continuous ongoing improvement". According to the Kaizen Institute, it is "recognised worldwide as an important pillar of an organisation’s long-term competitive strategy." It is considered to be one of the cornerstones of lean manufacturing.

Similar to lean manufacturing principles, there are fundamental principles that are embedded in every kaizen tool and behaviour.

The 5 principles are:

- Know your customer

- Make it flow

- Go to Gemba

- Empower people

- Make it transparent

Source: Kaizen Institute Consulting Group, Ltd. "The Core of Kaizen". YouTube. November 22, 2018.

Know your customer - identify their interests so you can enhance their experience.

Let it Flow - everyone in your organization should aim to create value and eliminate waste (MUDA). MUDA is a Japanese word meaning "futility, uselessness, wastefulness". Wastes can consist of overproduction, inappropriate processing, and defects. In manufacturing, MUDA does not add value to the customer's purchase.

Go to Gemba - "the real place". Value is created where things actually happen. Gemba refers to the location where value is created. Gemba kaizen embraces the skill set of an entire organisation. The belief is even the smallest improvements will create greater value in time.

Empower People - inspire and reward everyone for achieving production improvements, and provide a system and tools to reach them.

Be Transparent - speak, manage and educate with real data. Performance and improvements should be tangible and broadly visible.

Operation Excellence Through The Six S's

One of the concepts of kaizen, is to fully embrace excellence in any work environment. The Kaizen Institute recommends the "Six S's" to ramp faster to achieving overall success.

6S, (originally known as 5S plus Safety) is a lean process improvement tool. They are techniques to enhance productivity, quality and safety at the workplace. They are intended to eliminate waste.

1. Sort Out (organise)- if you are not using items in your workplace, discard or store them. A company's goal should be to have a streamlined working area.

2. Set in Order or Stabilise - have easy access to the items you use on a daily basis.

3. Shine (Scrub or Sweep) ensure everything is cleaned and functioning correctly with no clutter.

4. Standardise - set standards or develop a routine for performing the first three "S's", sorting, setting, and shining.

5. Sustain - Create a work environment that can follow the steps indicated on a daily basis. Creating a culture that embraces the 6S's is critical and will maintain the correct procedures.

6. Safety - Organisation will keep all employees safe in the work environment.

The benefits of implementing 6S are shown through the workplace becoming cleaner and safer, workflows becoming easier, and errors are minimised.

(You can read more in Chapter 6 - Lean Manufacturing Tools)

Chapter 3

Pros and Cons of Lean Manufacturing

Lean manufacturing is a comprehensive process. As with any process or system requiring change, there will be advantages and disadvantages.

Here are some of the benefits as well as the downside of adopting lean strategies.

Lean Manufacturing Pros:

- increase overall productivity

- reduced amount of space needed for actual production

- shortened lead times needed for manufacturing to improve flexibility and responsiveness

- faster time to market

- improve flexibility in production flow

- higher quality of goods

- less inventory

- fewer customer complaints

- lower costs

- better safety record

- higher morale

Lean Manufacturing Challenges:

- lack of the lean process understanding by top leaders in management

- time required to produce the results

- the required effort to sustain the changes with long term commitment (revert to your old ways of inefficient processes)

- maintaining engagement over time

- getting acceptance by employees

Chapter 4

How to Implement Lean Manufacturing Principles [Case Study]

Eliminating waste and controlling quality and inventory is the goal every effective manufacturer desires. Improving overall performance across their workplace requires tenacity and skill.

According to Lonnie Wilson, Author, "How to Implement Lean Manufacturing ", it also takes leadership and management. His belief is to shape and manage culture using the five cultural change leading indicators; leadership, motivation, problem-solving, total facility engagement and learning/teaching/experimenting.

"The things that make the TPS (Toyota Production System) unique among lean companies are not technical but rooted in culture."

Leadership / Top Management

In a recent study, surveyed managers affirmed top management's role was critical to implementing and enforcing new principles and practices.

The Role of Leadership in Implementing Lean Manufacturing (CC BY-NC-ND 4.0)

Based on a survey within the manufacturing sector, top management has been highlighted as the key success factor, particularly for SMEs (small and medium-sized enterprises). Leadership must have a plan. And they must be able to articulate the plan with every employee in the workplace.

Motivation to Embrace Change

"It is not the strongest of the species that survive, nor the most intelligent, but the one most responsive to change.” Charles Darwin

7 Techniques Lean Managers Use to Build Motivation Culture

Problem Solving

This a great example of where the PDCA (Plan Do Check Act) business approach comes into play. Companies need to work as a team. They will define a problem, execute a solution, review/revise results, and educate others on the results.

Total Facility Engagement

Employee engagement is paramount for change. Engagement can be facilitated through training, mentoring and coaching on all levels. Employee engagement will boost individuals, teams, and overall production and operational performance.

Learning/Teaching/Experimenting

Experimenting comes back to the use of continuous improvement (kaizen) "change for the better" at all times.

Lean Case Study: How Kaizen Creates a Culture of Continuous Improvement Through Employee Engagement

Location: Suzhou, China

Problem: Employees are not leveraged to their full potential and engaged in a continuous improvement culture

Solution: Create a culture of continuous improvement where all employees are actively engaged, and submit their ideas on how to improve productivity, quality, cost, safety and morale

While this is easier said than done, TT Electronics, Suzhou was faced with implementation challenges. Many of the employees and managers were excited on the science and concept of kaizen, however were slightly resistant with the time and process it would take to see success.

Management understood the need for clarification and created a clear, well communicated vision of the "idea concept" to avoid any misunderstanding.

A system was developed to help employees submit ideas easily via mobile phone, and a dedicated team was created to assign these ideas and follow up its performance. Communication was put into action with biweekly review meetings, best practice sharing via WeChat feeders, and annual kaizen idea focus week.

Key Approaches to Implement a Kaizen Idea System

Vision of TT Electronics, Suzhou Kaizen Idea Program

We used a 7 step systematic process to start improvements.

Step 1: Kaizen idea was explained with a proposed outline

Step 2: The idea was submitted in the WeChat App, a mobile text and voice messaging service.

Step 3: The idea was acknowledged by the dedicated team. Tip: Set up a cross functional team with one dedicated MLP (Master Lean Practitioner) to guide the team through the process.

Step 4: The team assigned the new idea to an "owner" to implement

Step 5: Kaizen idea closed when actions are successfully implemented by its owner

Step 6: Yokoken actions (horizontal deployment) shared by the idea committee if the idea can be used across an organisation.

Step 7: Yokoken actions closed by owner if the idea can be used widely

Process of TT Electronics, Suzhou Kaizen Idea Program

Engage employees with best practice sharing. The dedicated team should engage employees from all departments. We suggest two approaches from our experience:

- Management team should lead by example

- Identify the champions for their ideas and share their good experience within their own department.

Results:

During the initial idea implementation, TT Electronics, Suzhou received almost 3,000 valid ideas in 2016.

By 2018, the ideas were flowing with close to 10,000, with 100% of employees engaged in kaizen idea activities and more than 60% of the ideas implemented.

Group photo for key kaizen team (2018)

By implementing kaizen tools and principles, TT Electronics dramatically improved quality, lead time, cost, and employee morale.

For kaizen and the lean manufacturing principles to work well, every employee must be involved in every step of the process, every day.

Byron Zhang, VP/GM (Asia Pacific), TT Electronics adds:

"Implementing kaizen the right way is not necessarily easy or inexpensive. It's important that management lead by example, involve themselves in the workplace, understand real data, identify the problems to provide solutions. Secondly, the principles are not limited in manufacturing, but apply to daily work, environment and safety."

Chapter 5

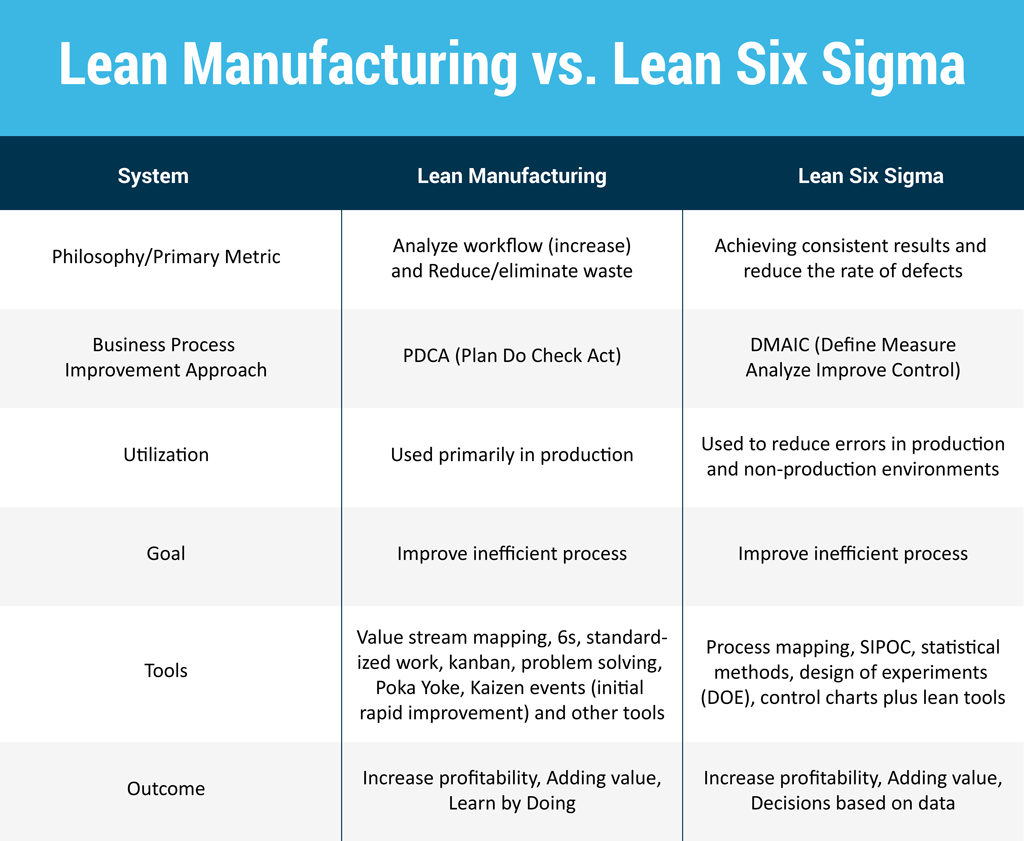

Lean Manufacturing vs. Lean Six Sigma

Both systems have the same goal just a slightly different approach.

"Essentially, Six Sigma and Lean systems have the same goal. They both seek to eliminate waste and create the most efficient system possible, but they take different approaches toward how achieving this goal. In simplest terms, the main difference between Lean and Six Sigma is that they identify the root cause of waste differently." Villanova University

source: Lean Manufacturing vs. Lean Six Sigma

Why choose one over another?

Lean Manufacturing and Lean Six Sigma can be more powerful used together. The two methodologies and principles go hand in hand. Lean is concentrated on waste removal and being more productive. Six sigma is structured on reducing the rate of defects and variation utilizing statistics.

Chapter 6

Lean Tools You Can Use

Lean manufacturing is a set of tools that can be applied to any system of manufacturing to enhance productivity, quality and safety in the workplace.

Like our infographic? Feel free to share it:

1. What is 6S all about?

It is the road to safety and organisation for any business. 6S is encouraged for a lean workplace. The lean process consists of:

- Sort Out

- Set in Order or Stabilise

- Shine (Scrub or Sweep)

- Standardise

- Sustain

- Safety

2. QCPC - Quality Control Process Charting

Highlight the "turn-backs" - anything preventing the product flow

3. VOC - Voice of the Customer

Understanding the needs of the customer and translating it into opportunities for improvement

4. Lean 6 Sigma

Problem-solving by using data and statistics, following DMAIC (define, measure, analyze, improve, and control).

5. Standardised Work

Defining the process clearly, timed to meet the customer's demand

6. Value Stream Mapping

Value stream mapping is a visual tool to highlight all the areas of waste, from the customer's order to the delivery of the product.

The EMS consulting group defines it as, "Value stream mapping is a practice developed by Toyota, where it is commonly known as Material and Information Flow Mapping. A value stream map shows all of the actions required to bring a product or service to a customer.

7. Error Proofing

Methods that help operators prevent and detect errors or defects

8. TPM - Total Productive Maintenance

Pro-actively maintaining equipment to minimise unplanned downtime, by utilising the whole workforce

9. QCO Quick Changeover

Minimise the time between switching from one product on a machine to another

10. Visual Management

Communicating the status of the process in real time by the use of visual indicators and systems

11. Pull Systems

Aligning the material flow with the direct customer demand so that only demanded products are produced

12. Cell Design

Configuring production processes to be flexible and aligned with the customer's demands

Conclusion

A lean organisation understands customer value. Applying lean manufacturing principles helps to increase revenue by providing a better quality product in less time.

TT Electronics customers get better value because our lean manufacturing system has zero waste.

The Global Manufacturing Solutions division of TT Electronics is a powerful resource for your local and global lean manufactured components. TT Electronics is the right fit for OEMs requiring high mix, low volume manufacturing.