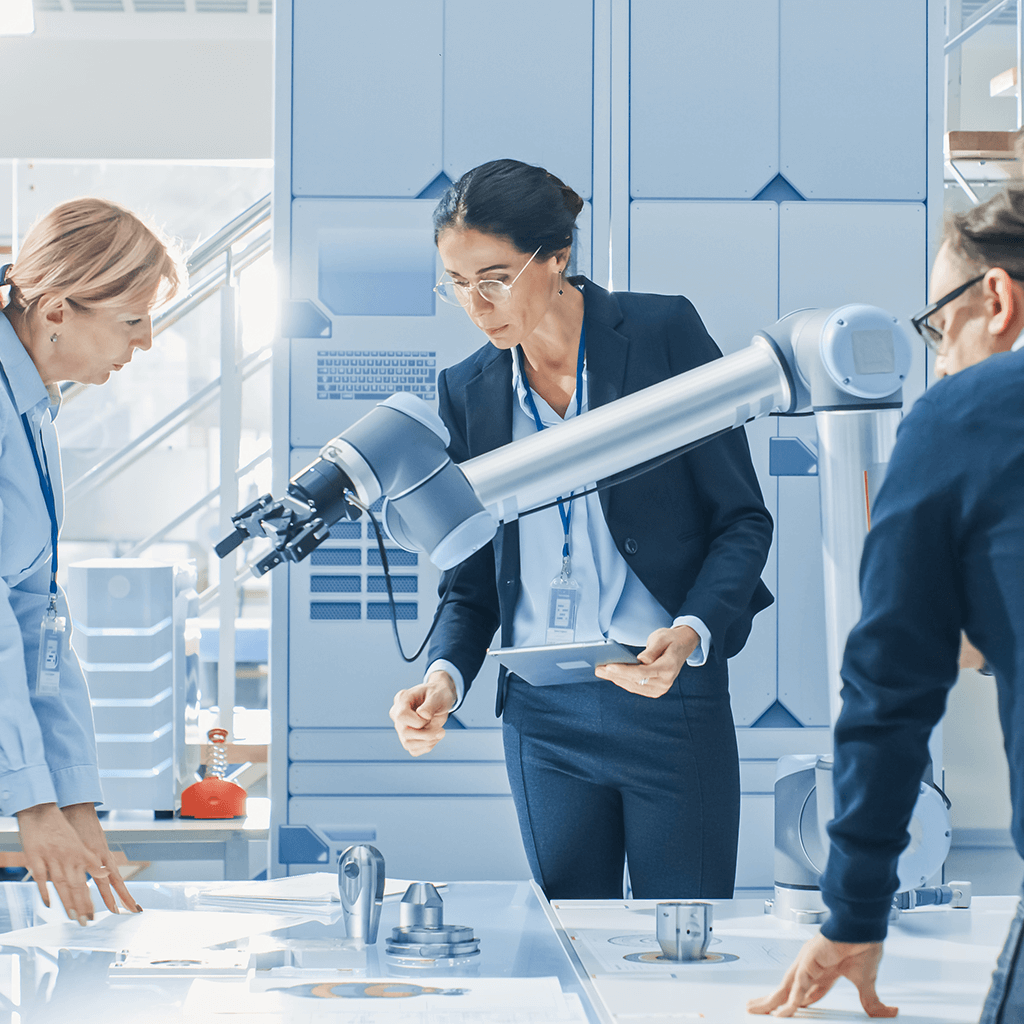

NPI & Engineering

Our team of engineers are here to guide and support OEMs through new product development.

- New Product Introduction

- Rapid Prototyping

- Test Development

- Project Management

- Design for Excellence

- Design for Manufacturability

Global Customers:

Our team of engineers are here to guide and support OEMs through new product development.

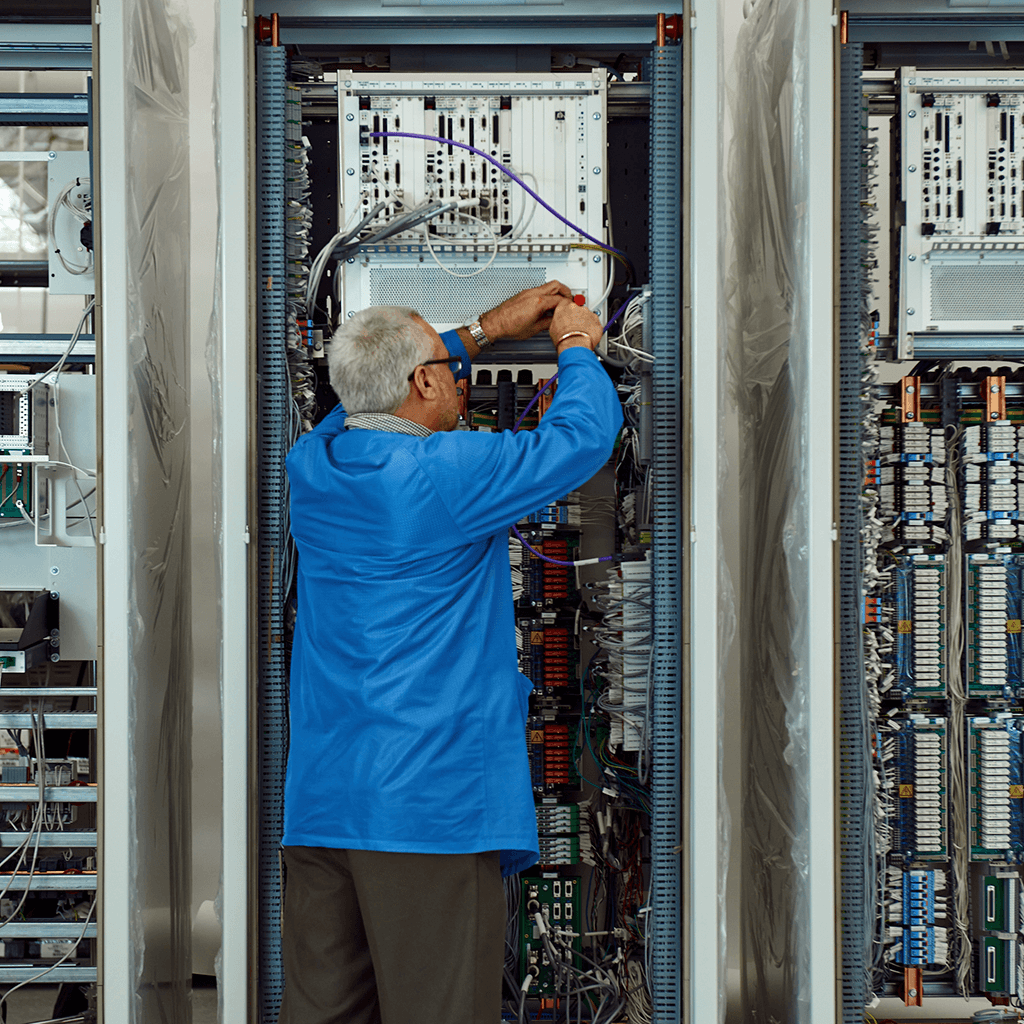

TT Electronics provides engineering experts from our global state-of-the-art manufacturing facilities, to design extensive varieties of printed circuit board assemblies (PCBA) to your exact specifications, from simple designs to complex system integrations.

The size, layers and manufacturer requirements are then determined. An appropriately complex PCBA "blueprint" is then created to visualise and assess how the components relate and work together. This blueprint then serves as a reference file for further collaboration. State of the art software tools facilitate this process.

Explore

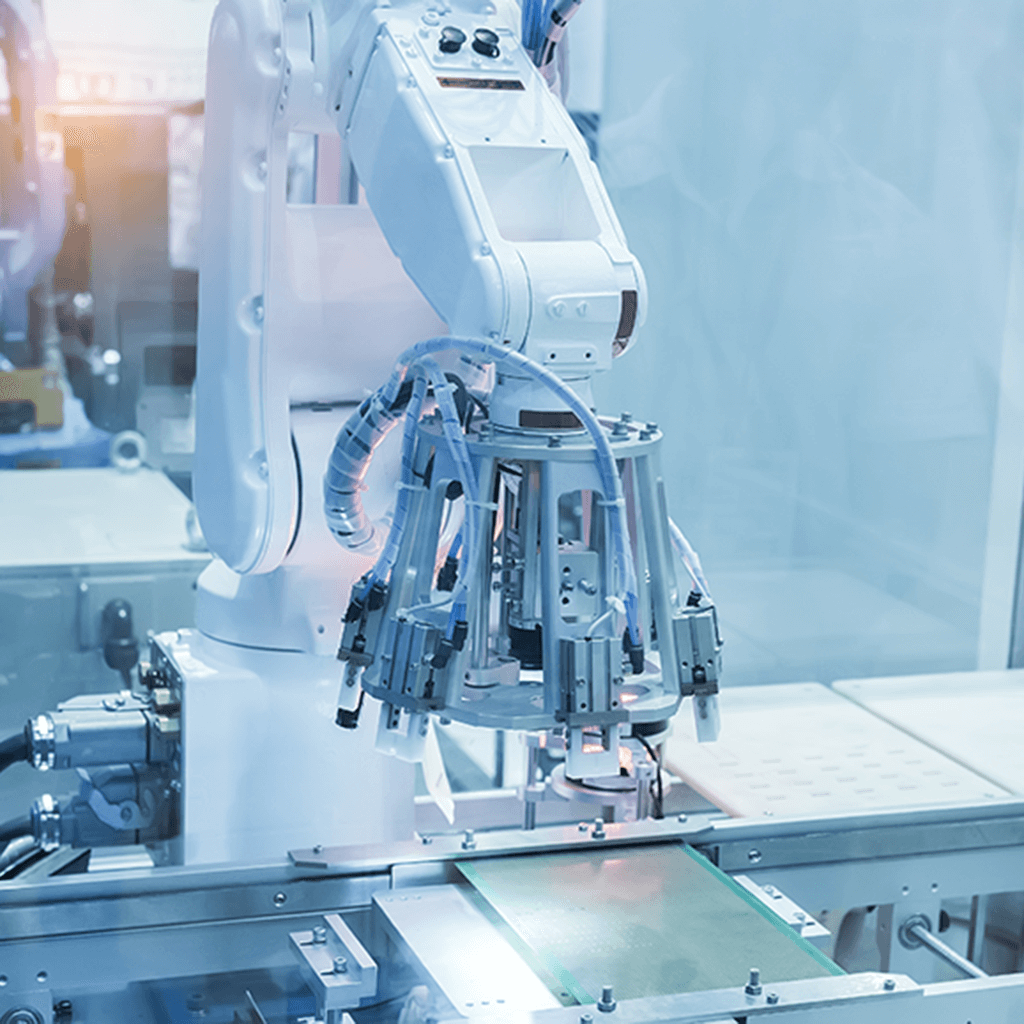

We provide extensive printed circuit board assembly (PCBA) capabilities and end-to-end solutions through full systems assembly and box build services.

The services will give you a streamlined process, save you time and money, resulting in a smoother, more effortless path to market. We have all the necessary capital equipment and processes to support your production needs and we can do this on a global basis in any one of our facilities. Every product shipped from our facilities will meet our customers' stringent order fulfillment and logistics demands.

Explore_1.png)

We offer customised cable harness and overmolded assemblies which provide durability and strain relief for the interface between cables and backshells.

We offer extensive production level test services, as well as environmental and investigative testing to help maximise product reliability.

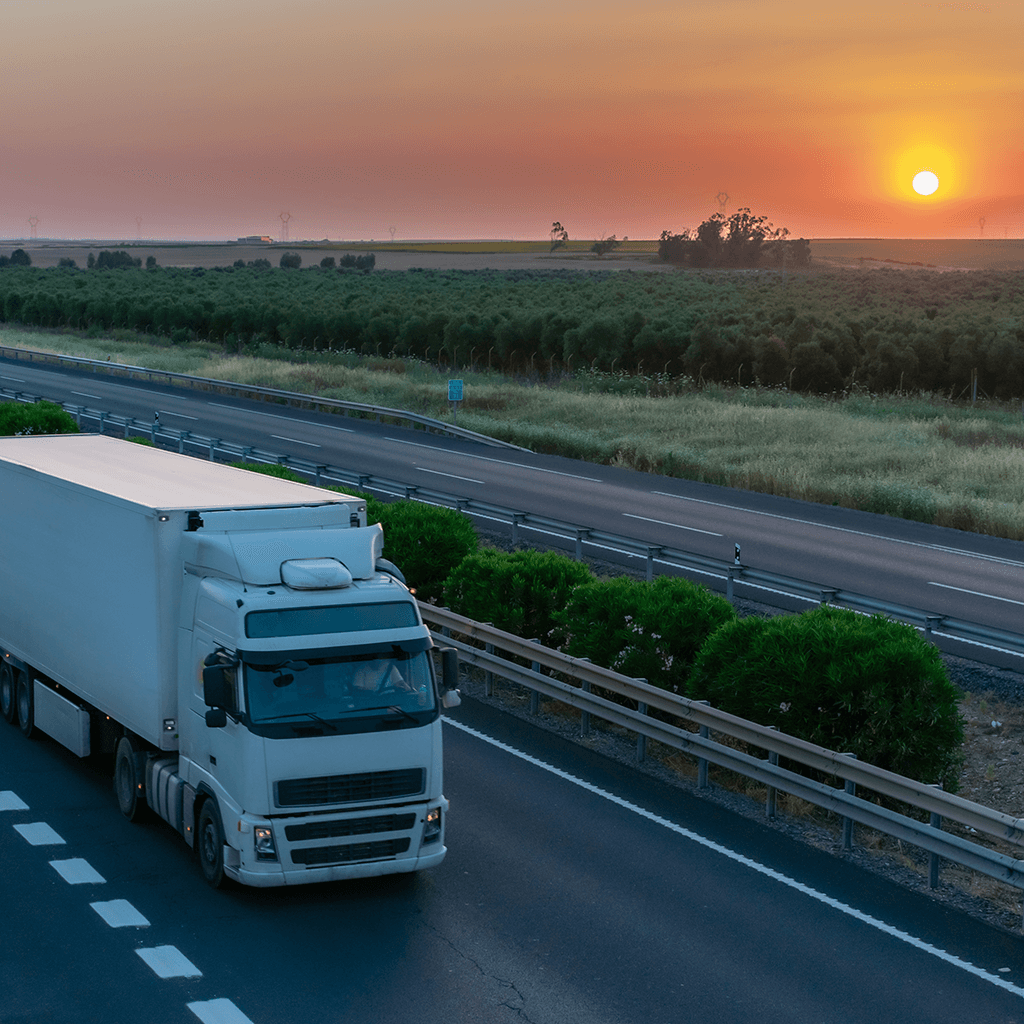

The optimisation of your global supply chain requires an EMS partner who has outstanding electronics supply chain management (SCM) and can bring your product to market efficiently. This means removing as much risk as possible by working with a leader who understands how to seamlessly integrate electronic components suppliers and speaks the language of engineers and international customs agents, so delivery avoids any import or export delays and is on time, every time.

_1.png)

Clean Room Manufacturing to Prevent Harm

TT Electronics’ clean room provides a production environment with minimal pollutants, ensuring that sensitive electronics are not harmed during the manufacturing process. The equipment located within the clean room itself is specifically designed to emit minimal levels of air contamination. If you have electronics manufacturing needs requiring special care, TT Electronics can provide you with a powerful clean room solution.

DISCUSS YOUR CUSTOM SOLUTION

F35

F18

Airbus A220

Laser Guided Munitions

Gulfstream G700, G650, G600, G550, G500, G450

Urodynamic Testing systems

Mobile X-Ray Systems

Handheld Medical Spectroscopy Systems

Clinical Chemistry/Immunoassay Systems

Radiotherapy Equipment

Semiconductors

Security

Cyber Solutions

Renewable Energy

TT is a true partner. They are exceptionally responsive to our needs, and their engineering support sets them well ahead of the competition. Their early supplier involvement on our next generation programs has enabled us to work through technical challenges and resolve things early in the design process.