Automation and robotics enabled by advanced sensors technologies is revolutionizing every aspect of modern medical systems and procedures, driving wide adoption of remote monitoring, analysis, robotic surgeries, and automated medication dispensing equipment. Highly specialized broad-spectrum silicon PIN photodiodes are used for non-invasive tissue oximetry monitoring during surgery and under anesthesia. Slotted switches and optical encoders measure the precise position, speed, and direction of motion of vials during test sample collection and analysis. Reflective sensors are commonly used in dispensing equipment and patient monitoring.

Continuous drive for high reliability in performance critical medical application often contends with the need for portability, miniaturization, and cost reduction of homecare medical systems. Optimally low costs could be achieved by selecting commercial-off-the-shelf COTS sensors with their reliability quantified by MTBF/FIT (mean time between failures/failure in time) studies.

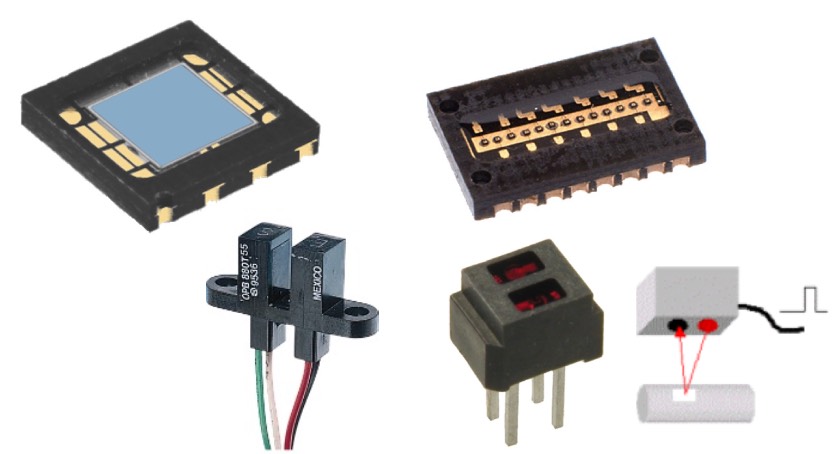

Tissue Oxygenation Sensor OPR5913, Multi-channel pill counter monolithic optical array sensor, Slotted switch for motor home position detection in portable hemodialysis system for renal therapy equipment, OPB606 reflective sensor for tubes detection in infusion pump.

The most optimum and, perhaps, the best overall cost of ownership could be achieved by employing highly integrated, miniature sensors such as OPB9000. This new generation of smart sensors is low cost because it is mass produced using highly automated assembly and test equipment. Due to its programmability, it is easily customizable to a variety of different applications, including liquid sensing.

Microfluidics, however, is a largely overlooked area of medical application that requires fine-tuned sensor solutions for liquid level detection, bubble detection, liquid presence detection, plasma separation in blood analysis, and many other applications with relevant bio-fluids.

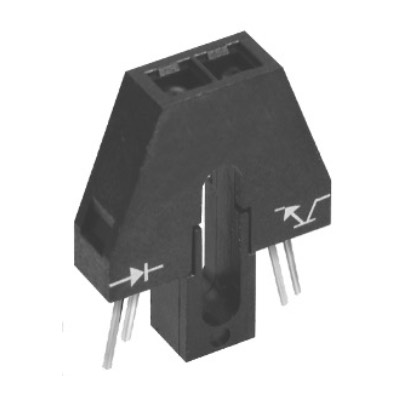

Focused reflective optical sensor OPB703 is used in medical dispensing equipment to detect marks in a reflective code disk.

The two most common ways to detect fluid in a tube are ultrasonic and optoelectronic methods. Both methods use electronics to detect changes in viscosity, transmissivity or movement of fluid in the tubing. Optoelectronics detects the presence of the fluid in the tube, as well as bubbles, and in some cases, the type of fluid in the tube. Under controlled conditions, this can be a simple process using a microprocessor or comparator to interpret the output signal of the optoelectronic sensor.

TT Electronics has developed a complete family of liquid sensors under OPB350 product line, including OCB350 calibration modules, to address challenges in microfluidics and fine-tune performance for various tube diameters, different liquids, liquid level detection, and bubble detection applications. This OPB350/OCB350 family of COTS liquid sensors is extremely cost effective elegant and snap-on easy to use sensing solutions for medical applications.

Snap-on tube OPB350 liquid sensor.

This sensor consists of an infrared light-emitting diode (LED) and a photosensor. The LED emits light at a specified wavelength, which is sent through a tube that contains air or liquid. The internal walls of the tube reflect some light, reducing the amount of light received by the photosensor. When fluid is present in the tube, the number of photons picked up by the sensor changes, altering the output of the photosensor. Several factors affect the performance of the optoelectronic sensor.

To get the most out of optoelectronic sensors, here are a few tips to keep in mind:

The optimizations discussed above not only allow for a better performance of the system, but also enable lower overall costs due to increased yield and longer life of such systems.

Identification of different materials or fluids can be achieved by monitoring the output current of a phototransistor across a resistor, utilizing either a microprocessor or a comparator circuit to detect various states: the presence of a tube, air in the tube, saline solution, blood, water or specific Hematocrit levels. By adjusting the current drive on the LED, or changing the sensitivity of the photosensor measurement technique, minor optical transmission changes of the fluid can be identified to recognize different fluids, such as Hematocrit %. Fine-tuning the circuit for a specific application can be accomplished using TT Electronics OCB350 family sensors, which already incorporate a built-in calibration circuit.

Ultra-portable power adapter uses GaN technology to deliver fast 360W output charging

At TT Electronics, the commitment to people as the cornerstone of success is showcased through the remarkable achievements of its employees.

TT Electronics is proud to announce that its Juárez facility has been awarded the esteemed Recognition as a Company Committed to Human Rights by the Chihuahua State Human Rights Commission (CEDH).